Company Profile

Zhejiang Duoli Plastic Co., Ltd. is located in the historical and cultural city - Quzhou, which is the second home of Confucius. As a city in South-East China, Quzhou is only one hour outside of Hangzhou, 2 hours outside of Shanghai. It enjoys excellent logistic advantage, convenient transportation, a long history and outstanding talents.

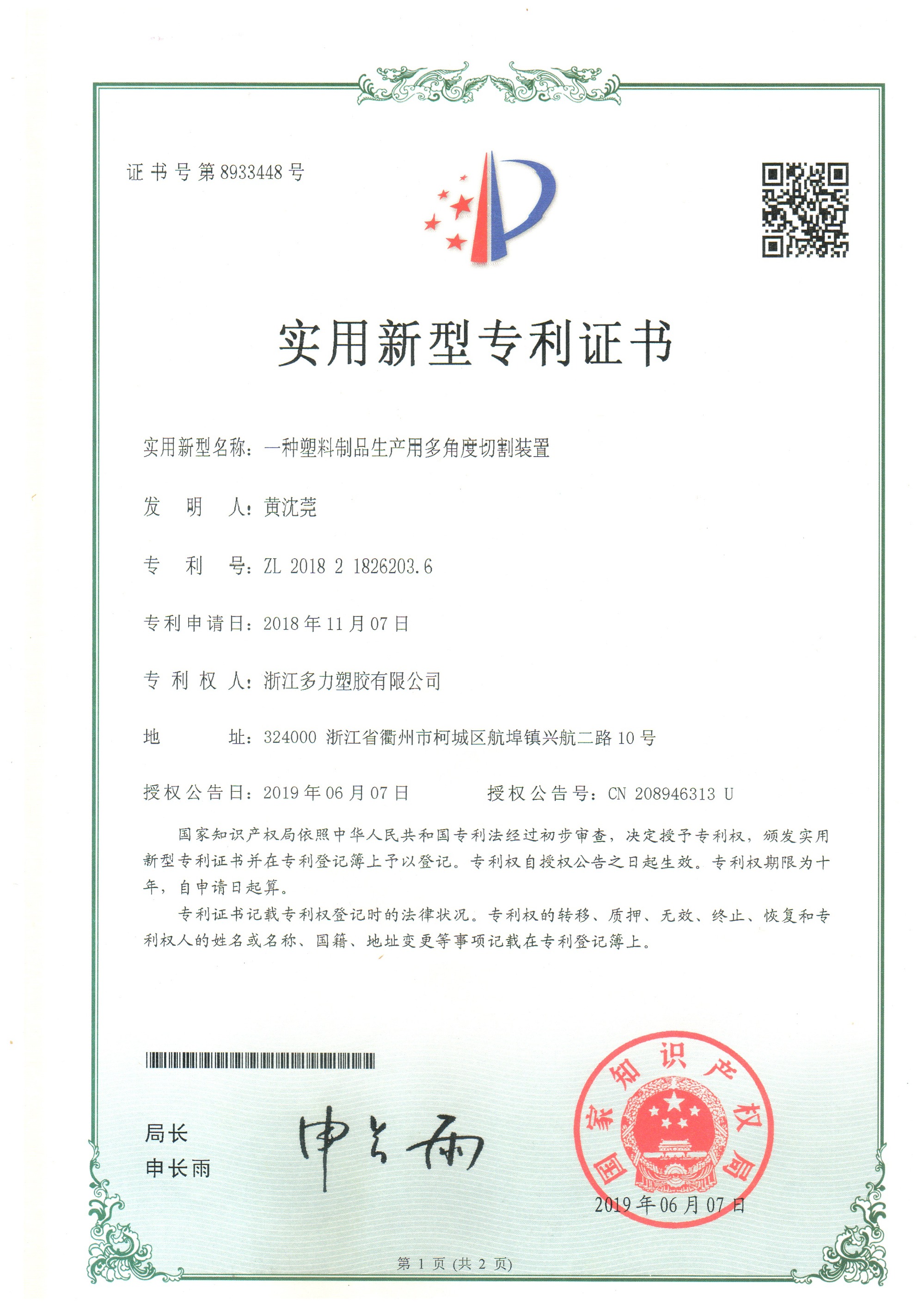

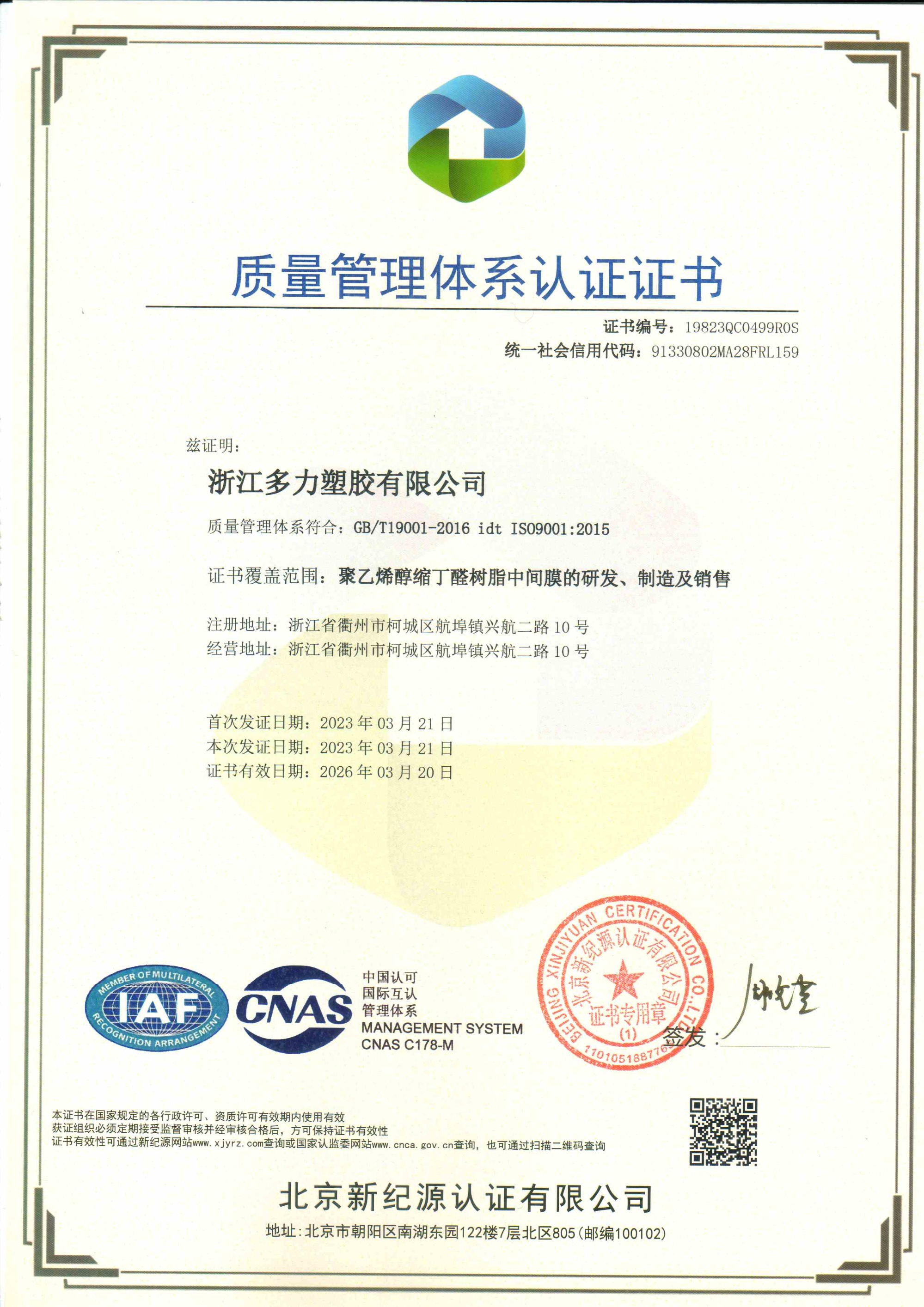

Zhejiang Duoli Plastic Co., Ltd, covers an area of 5.8 acres, in which phase 1 standard workshop and supporting facilities floor space covers 26,640 m2. With a total investment of 120 million yuan, the company owns 2 PVB film production lines, and the output reaches 8,000 tons. We produce 0.2~2mm thick, 500~3200 wide PVB film in more than 20 colors and customization is also available. The company targets global high-end market, insists the entrepreneurship of integrity, innovation, development, win-win cooperation, strengthens inner management and brand publicity. Introduced from Europe and America, our complete equipment can test production online in real time during the production. We also have complete detection system to fully test the end products. The quality of our products reaches the domestic leading level and has passed ISO9001:2015 and ISO14001:2015 quality management system certification. The company has a strong R&D force, and is a member of Zhejiang Glass Association, Shanghai Glass Fiber Reinforced Plastic Industry Association, and a director of Zhejiang Shanhai Cooperation Association.

With the management idea of “quality and customer service first”, Duoli Plastic Co., Ltd, forges ahead and strives for innovation to be a leading company worldwide.

With the management idea of “quality and customer service first”, Duoli Plastic Co., Ltd, forges ahead and strives for innovation to be a leading company worldwide.

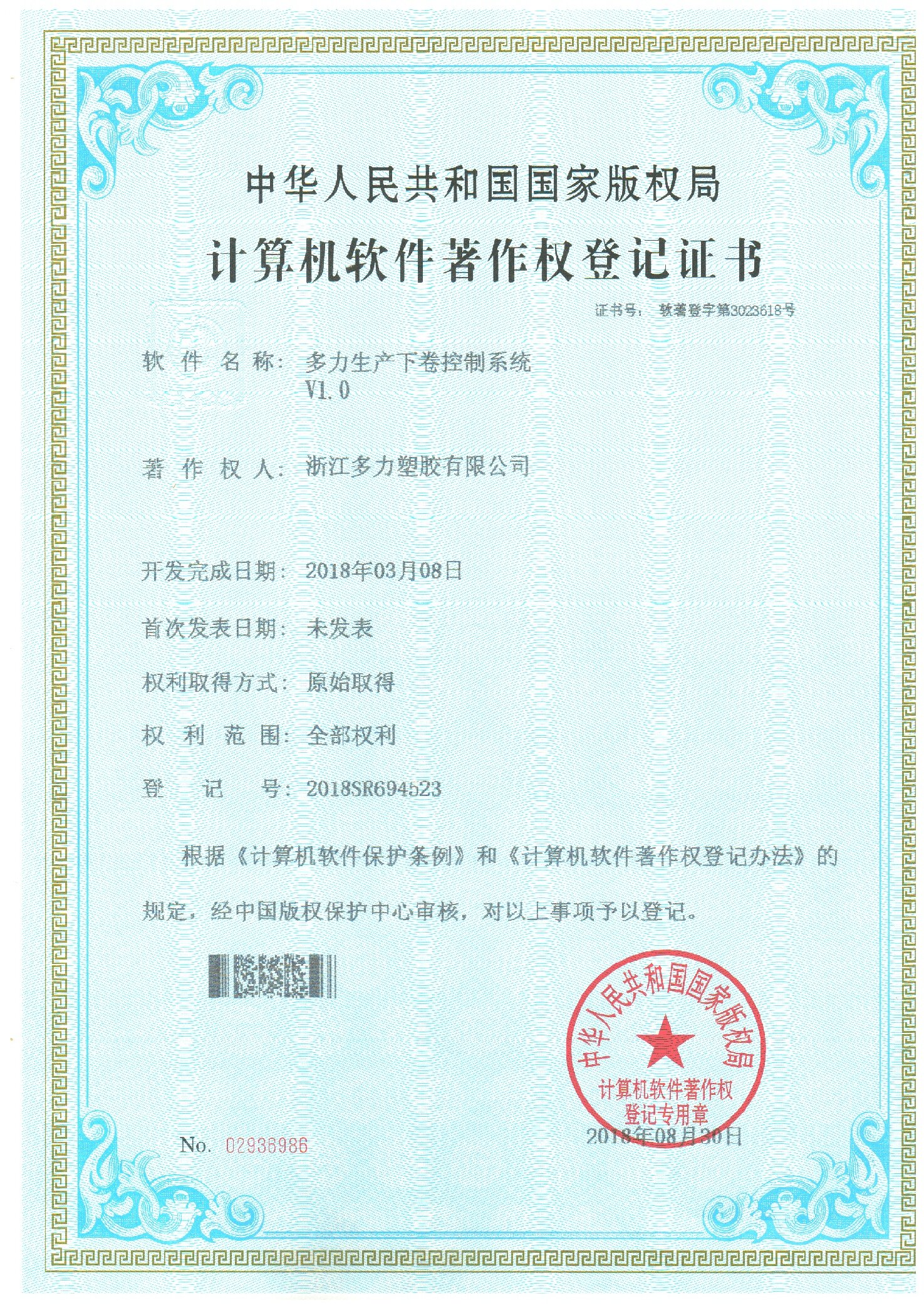

Production Control

Professionals monitor the production in real time to ensure the normal high-speed operation of the machine.

All workers wear protective coveralls, keeping safety and clean production environment.

Central control room, 7x24 hours all-round-the-clock supervising production.

Full Automotive Rolling Machine, with high efficiency of production, short delivery time to customers.

The whole line is equipped with detection system (humidity / thickness scanner, online impurity detection system, etc.), and the finished products are inspected to ensure product quality.

The workshop is equipped with 100,000 Grade air shower system, and at the entrance with advanced online impurity detection.

Video Introduction

Manufacturing Technique

1. Glass Cutting, Cleaning and Film Cutting

- Slice the glass accurately.

- Check the glass surface and clean the grease and dirt. Tap water can be used for cleaning.

- Clean again with soft water. Water quality suggested<30μS,hardness<10 PPM,temperature:40-60℃.

- Blow-dry the glass to prevent dirt.

- Film cutting shall reserve 2~5mm over the glass size according to the actual production requirements.

2. Glass Bonding

- Glass Bonding Room

- The temperature of the glass bonding room shall be controlled constant between 20~25℃ and the humidity is between 23%±2%. The room shall be no dust inside and the equipment shall be kept clean. The workers all keep the uniforms, caps and gloves clean to prevent dust, particles and hair sticking to the films.

- Glss Bond Conditions

- The surface temperature of the glass is suggested to be between 20~30℃ and the maximum is no more than 40℃. The surface temperature of the film is suggested to be between 20~25℃. Check again for the cleanness of the films and glass and if the glass and film match.

3. Preloading and Venting

- Cold Vacuuming and Heat Vacuuming

- Vacuuming Venting:Vacuum degree 580~680mmHg, temperature 20~25℃, pressure -0.095~-0.1MPa. The cold vacuuming time for continuous vacuuming is about 20 minutes. If it is discontinuous vacuuming, the cold vacuuming is about 30minutes.

- Heat Vacuuming: The surface temperature of glass is 100~120℃, the time is 30~45 minutes. The temperature is between -0.095~-0.1MPa. Take out the glass when the temperature is reduced to 60~80℃.

- Roll-in Venting

- Preheating of the thermostat→The surface temperature of the bonded glass is 20~30℃ and humidity about 25%→First roll-in, the pressure is 0.2~0.5MPa, the roller spacing is less than the thickness of the bonded glass by about 10%→Thermostat→The surface temperature of bonded glass is 65~80℃→Second roll-in, the pressure is 0.3~0.5MPa, the roller spacing is less than the thickness of the bonded glass by about 15%~20%. Keep continuous operation to keep the temperature of the thermostat constant.

4. High Pressure Forming

- During the whole process, the heating & pressurization and cooling & decompression should be operated slowly. The following processes are for reference: Heating & pressurization→The temperature is increased to 60℃ and the pressure is 0.4MPa→The pressure is increased to 135~140℃→The pressure is increased to 1.05~1.28MPa→Constant temperature for 30~60 minuted (It is determined by the thickness and quantity of the glass in the pot.)→ Keep constant pressure and reduce the temperature until it is reduced naturally and lowly to 90℃→ Reduce the temperature to 45~55℃ and exhaust.

5. Package And Storage

- Rolls of PVB films are vacuum-packed with aluminum foil film. There are 2 means of external packing: cardboard tube and wooden case. Generally the PVB films with a width less than 1200mm (including 1200mm) are packed in cardboard tube or cartons, while the ones width a width more than 1200mm are packed in wooden cases. Qualified products are packed with certificated of qualification, packing list, etc.

Cooperative Partner

Product Test Report